+1 866-700-9858

6923 Narcoossee Rd. Ste. 612

Orlando, Fl. 32822

NEWSROOM

ACD America Corporation’s Commitment to Excellence in Control Valves and Instruments for the Process Industries

The Future Is Now For Predictive Valve Maintenance

Process manufacturers have pursued the elusive goal of predictive maintenance for decades because they know that deploying resources and focusing on equipment that is about to fail, while allowing healthy devices to remain in service, will save millions in maintenance costs. Avoiding unplanned outages and shutdowns would undoubtedly save millions more. It stands to reason that every company should be run this way, yet few have accomplished that goal because predicting the future is notoriously difficult.

This article discusses a variety of diagnostic and data-driven initiatives that make predictive maintenance possible. These efforts have been years in the making and are bearing fruit in the automated valve industry, with ongoing development underway.

Proactive versus reactive repair

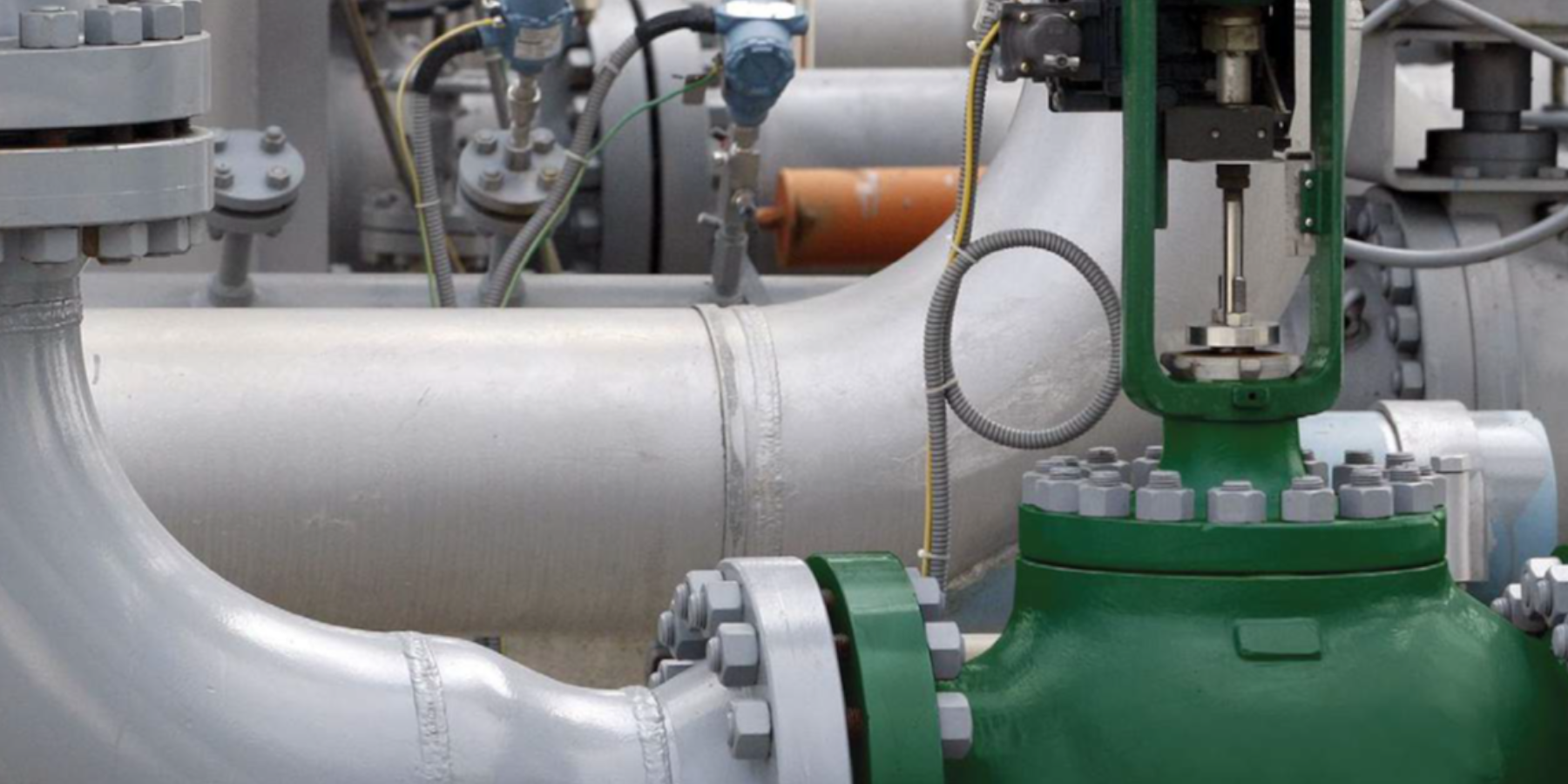

Automated control and on-off valves are critical components in a vast number of processes, and their unanticipated failure can cost millions of dollars annually. Unfortunately, many automated valves offer no obvious hint of developing problems. When the PID controller is set to automatic, which is typically the case, it compensates for degrading valve performance, so the loop continues to function, albeit with reduced performance. Eventually the valve fails completely, upsetting the process or forcing a shutdown.

In reality, there often are hints of an impending failure, but these signs can be quite subtle (Figure 1). Still, if these signs could be detected and acted upon, it would be possible to gather the necessary repair components, schedule a brief outage or bypass to perform the repair, and minimize production loss.

Figure 1: A valve will often exhibit subtle signs of degradation well in advance of outright failure. If these conditions are noticed and appropriate actions are taken, unplanned outages can be avoided.

The key ingredient that makes this predictive maintenance possible is data, and ideally the more information one has, the more accurate predictions can be. Historically, automated valve data has been limited to valve position, but with every generation of smart diagnostic digital valve controller, more information has become available.

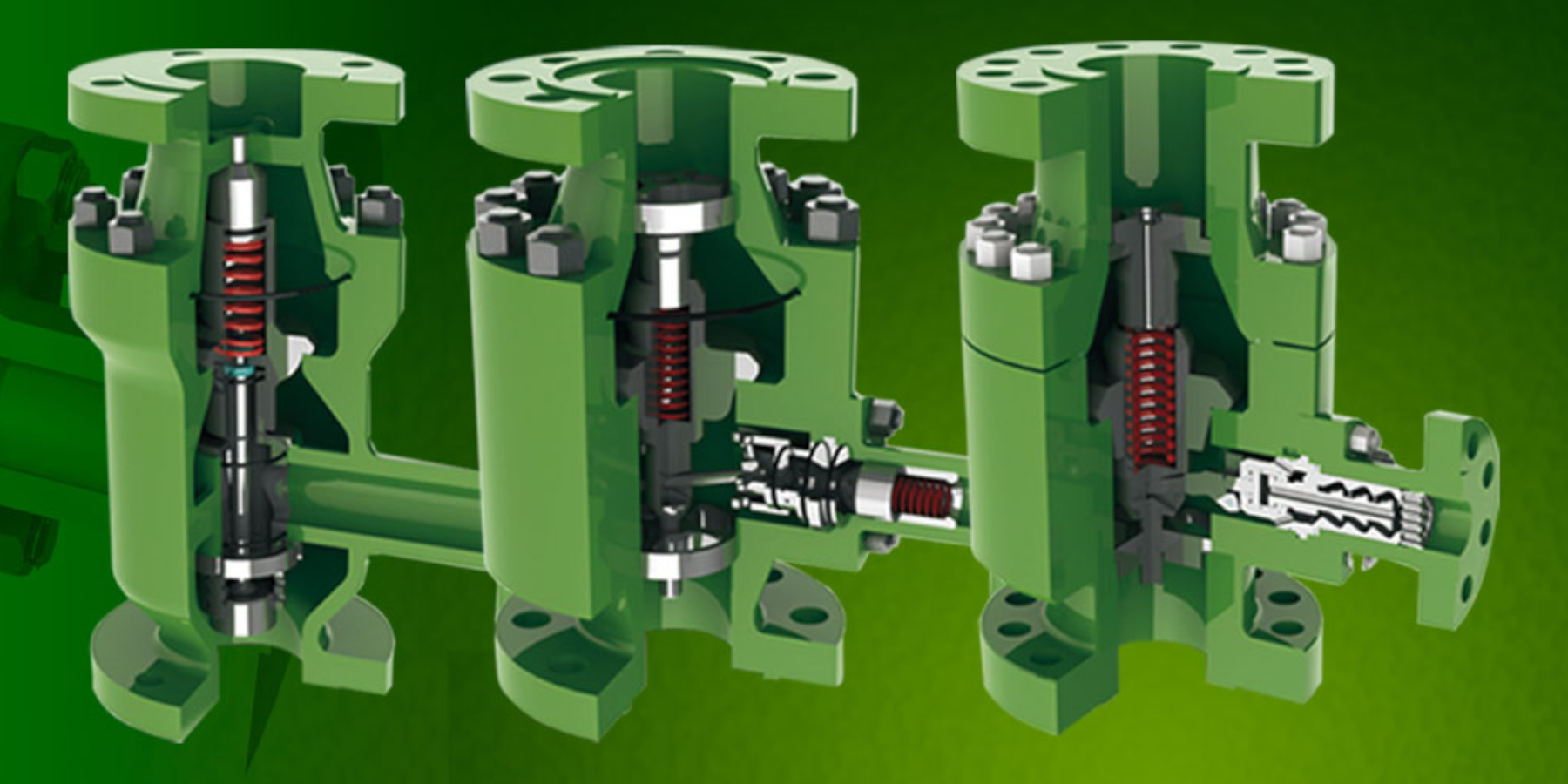

These digital valve controllers employ an array of sensors to monitor the valve and detect abnormal conditions as they develop. Higher-tier units allow both offline and online monitoring. Valve signatures and as installed data can be captured and compared with future tests to note discrepancies. These types of online measurements capture ongoing valve performance and transient problems that can otherwise be difficult to detect.

The next generation of digital valve controllers are already well into the design stage, and they will provide even more data that can be utilized to monitor valve operation, packing performance, system integrity and much more. New software apps will automatically analyze all available data to provide insights and recommendations.

Data is only useful if you use it

Data is certainly a key requirement to enable predictive maintenance, but no predictions are possible unless a knowledgeable entity receives that data and properly evaluates it to draw accurate conclusions. The whole process is stymied by host of problems.

- The currently installed valve controller may be an older model lacking the ability to sense and capture the necessary data.

- The digital valve controller may capture the data, but it has no way to serve up the data, unless a technician goes to the valve and accesses the information directly.

- The digital valve controller may be tied to some type of maintenance network and the data transmitted to a common location, but there are no resources to look at the data. Even if resources are available, they may lack the experience and knowledge to accurately interpret the information and draw actionable conclusions.

These issues are being addressed in a number of ways. The first problem is resolving itself with time. As older valve positioners fail, most users are replacing them with diagnostic digital valve controllers, which have improved sensors and advanced communication technologies. However, there are tiers of performance with these devices, with higher-end equipment providing out-of-service and in-service diagnostics, as well as partial stroke testing.

If a company wishes to position itself for predictive maintenance, it may need to invest more in the digital valve controller for any repaired or new valves. This is particularly true of any valve that is critical to production or operates in severe service. Paying for the higher-tier digital valve controllers for these valves will almost always pay for itself in short order due to improved diagnostics capability, lower maintenance costs and increased uptime.

The second issue, that the data is captured but not transmitted anywhere, has been addressed in a variety of ways, with further improvements already in development. Higher-tier digital valve controllers have multiple options for transmitting the data via a number of different wired and wireless communication protocols (Figure 2).

Figure 2: One common method of valve data capture utilizes the control system connections to transmit the information to a maintenance database, which monitors for problems.

Predictive maintenance is only possible if the data can be continually accessed and monitored in near real time. Therefore, the most successful plants have some means of pulling the data up through the control system and transmitting it to a central location where it can be reviewed, or transmitting the data directly from the digital valve controller to its intended destination.

Transforming data into savings

Perhaps the most difficult aspect of a predictive maintenance system is finding a knowledgeable resource that can assess the information, detect developing issues and initiate actions that can address the problems in advance of outright failure. Fortunately, a number of solutions are already in place, with several more in development.

Valve data management packages, like Fisher FIELDVUE ValveLink software, are an on-site solution that can automatically perform scheduled online testing of each valve as it operates, as well as continuously monitor and alarm issues with air pressure, performance degradation and packing. Future software enhancements will use software apps with built-in machine learning and artificial intelligence to flag developing problems and suggest solutions.

If the plant lacks the resources to monitor valve information, it can securely transmit the data to trained automation experts located remotely, who can serve as an extension of on-site staff. The experts can communicate developing long-term issues to plant personnel, as well as problems requiring immediate response (Figure 3).

Figure 3: When a plant lacks the proper knowledge or resources, critical valve data can be securely transferred to remote experts for continuous monitoring.

These services free plant resources to perform other tasks by detecting degrading performance and impending failures before operations are impacted. They also provide plant personnel with access to valve experts on an on-going basis for consultation on performance, along with recommended corrective measures.

Data investments pay dividends

A herbicide plant used advanced control valve diagnostics to transition from reactive to predictive maintenance, reducing annual maintenance costs by $230,000. In one case, the plant saved nearly $100,000 an hour by detecting and addressing a developing control valve issue before it shut down the unit.

A refinery identified 26 critical valves in their hydrocracker unit that could cause unplanned shutdowns. The plant lacked resources, so they engaged their valve vendor to provide remote services for continuously monitoring these valves and reporting issues. The service detected a developing air leak on a large anti-surge valve, as well as issues with several heating valves. Using this information, all repairs were planned and executed without production impact, avoiding a $5.6M unplanned outage, and saving $400,000 a year by improving performance of the heating unit.

Smart digital valve controllers, like this Fisher FIELDVUE DVC6200 SIS Digital Valve Controller, employ a variety of sensors that detect air, actuator, packing and valve problems.

A combined cycle power plant saved $68,000 in one outage after installing a number of upgraded digital valve controllers and implementing diagnostic alert software, enabling the facility to focus repair efforts more efficiently. Annual maintenance cost reductions totaled $33,500, and planning for outage repairs was significantly improved, particularly by ordering repair parts in advance.

Conclusion

Predicting the future is not easy, but it is possible when the right data can be gathered and reviewed by a knowledgeable entity. Many existing digital valve controllers can provide the required data, and next generation digital valve controllers will gather even more data. Once captured and transmitted to the right repository, advanced software tools and remote experts can translate the information into specific actions that can be taken to resolve problems and avoid unplanned failures.

Significant advances in digital valve controllers — including newer communication technologies like Ethernet APL and local real-time control — are already in progress, rapidly improving prediction accuracy to cut maintenance costs and increase uptime.

Wise investments in equipment upgrades or new equipment specifications, along with remote expert services when needed, will pay big dividends in the future. Predictive maintenance is finally possible, and it will only improve with time.

Saurabh Pathak is the digital valve global marketing director at Emerson Automation Solutions, with global marketing responsibility for next-generation product development of valve prognostics, hardware and sensor-based technologies that tie into analytics-based valve management software. He has been with Emerson for 16 years, working across North America, Asia-Pacific and the Middle East, where he is currently based. Pathak holds a bachelor’s degree in Electrical & Computer Engineering from Queensland University of Technology in Australia.

Naman Tahan is the director of engineering and operations for Digital Valve Services at Emerson Automation Solutions, with global responsibility for all deployment and performance aspects of the company’s valve condition monitoring remote services. He has been with Emerson for the past 28 years in various sales, operations and project managements roles, and he is currently based in Houston, Texas. Tahan holds a bachelor’s degree in Electronics Engineering from Aleppo University in Syria.

Emerson

Category

Tag List

Recent Posts