+1 866-700-9858

6923 Narcoossee Rd. Ste. 612

Orlando, Fl. 32822

NEWSROOM

ACD America Corporation’s Commitment to Excellence in Control Valves and Instruments for the Process Industries

Alternative Control Valve Repair Solution yields Savings

A new hybrid repair/replace control valve repair solution reduces repair time by 60% and increases uptime significantly.

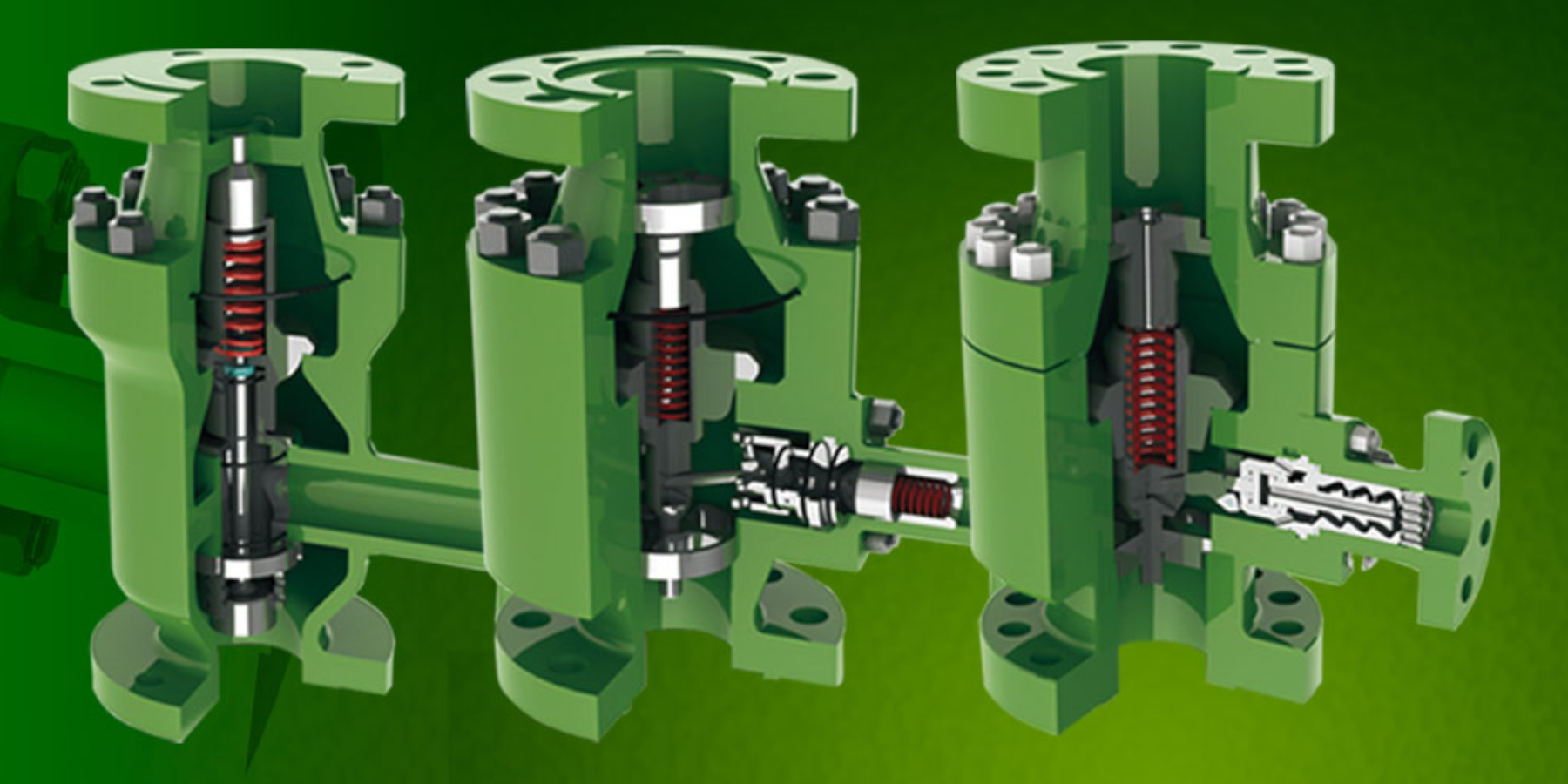

Figure 1: Control valves typically have a broad array of internal components that may require replacement during a repair. All these parts must be available before a valve repair is attempted, and proper reassembly is critical for valve performance.

Control valve repair has historically been an expensive and challenging aspect of plant maintenance. Each valve has a broad array of internal parts, and it is difficult to know what parts require replacement until the valve has been pulled from service and completely disassembled.

Even if the right parts are available, it takes a fully trained technician to diagnose, repair and properly reassemble the valve to restore it to functionality. Adding to the difficulty, the precision required to do this work means it can typically not be performed in the field, but instead must be done in a repair shop.

Fortunately, a new option dramatically simplifies the control valve repair process with a streamlined and complete approach, using a single assembly instead of multiple small parts.

Traditional control valve repair

Control valves are critical for process performance, and periodic maintenance is required to keep them in top operating condition. The removal of a control valve usually affects production, so there is great incentive to keep the repair cycle as short as possible. Though diagnostics indicate a performance issue within a valve, it is often difficult and even impossible to determine which exact component is failing without taking the valve apart to inspect it.

Control valves also represent a significant investment for industrial plants, so a simple replacement of the valve rarely makes financial sense. That leaves maintenance personnel with little choice but to pull the valve, disassemble it and identify and replace the failed components. They must then put the valve back together, test it to some extent and return it to service as soon as possible to restore production.

While that effort sounds straightforward, it usually proves quite difficult. The first challenge is the sheer number of components within a typical control valve (Figure 1). Twenty or more parts may make up the internals of a valve, and all must be available during the repair process since it is virtually impossible to identify the specific failed part in advance.

Assuming the proper parts are available, then the failed components must be replaced and the valve correctly reassembled. This effort requires a fully trained technician who is familiar with the control valve internals and understands the valve repair process. Control valves have very tight and specific tolerances, so the slightest error can significantly impact performance.

Once the repair is complete, there is still the risk that the problem was never fully identified, and the control valve may still fail to perform as required. In this case, the valve must again be pulled from service, disassembled and additional components replaced to address the issue. During this time, the control valve remains out of service and production has likely been negatively impacted. In some cases, the absent control valve may force a complete unit shutdown.

Figure 2: A trim cartridge replaces up to 20 individual internal components with one drop-in assembly and two supplied gaskets. It requires minimum training to install and makes inline valve repair possible, significantly reducing the time required to fix and return the valve to service.

Trim cartridge alternative

An innovation in control valve repair has recently been introduced that offers significant advantages over the traditional valve repair method. A trim cartridge (Figure 2) is a single, pre-assembled repair solution that replaces all the components shown in Figure 1. This includes a valve bonnet plus all standard trim and packing replacement parts, along with a plug and seat assembly that is capable of Class V shutoff.

A trim cartridge is a single, ready-to-install repair solution containing all the replaceable trim parts incorporated in a pre-assembled, leak-tested and serialized package. Installation just requires a straightforward replacement of the bonnet and trim (Figure 3), which can be completed in the field by plant personnel without removing the valve body from service.

This conserves valuable trained technician resources and significantly reduces downtime because the overall time to repair is typically reduced by 60% or more. More importantly, the repair replaces all serviceable parts plus the bonnet and does not require significant field adjustment. This dramatically improves the likelihood that the repair will be successful the first time, with the control valve performing as expected when returned to service.

A Fisher trim cartridge, for example, is backwards compatible for Fisher easy-e ET and EZ series control valves and it incorporates ENVIRO-SEAL packing as a standard offering. The Fisher trim cartridge assembly is offered in valve sizes one through four inch, includes both linear and equal percentage trims, and is offered in a variety of trim and component materials.

This provides a simple means of repairing older valves, while simultaneously reducing packing emissions by replacing the original packing with a low-emission upgrade. The packing arrangement in the trim cartridge is field serviceable, so the packing can be replaced in the future if necessary.

Video 1: A trim cartridge installation replaces the bonnet and all trim parts, and it can be performed without removing the valve body from the process.

Repair versus replace

A successful maintenance strategy considers the cost of repairing equipment against the cost of replacement to determine the most cost-effective means of operation. In the past, many plants had a large, trained technical staff onsite, so repair often made sense, even if a control valve required a major overhaul. Now, many facilities have a significantly reduced maintenance force and trained valve technicians are far less prevalent and available.

Under these conditions, valve replacement for worn valves, and partial replacement strategies like the trim cartridge, offer significant economic advantages over the traditional valve repair paradigm. These methods are even more favorable when one considers the significant production losses associated with a lengthy valve repair cycle. If the valve can be brought back into operation in a short time, the quick turnaround translates to higher production rates and profits.

Evaluating options

There are a number of situations where a trim cartridge is a better alternative than opening the valve, diagnosing the issue, hoping the correct parts are on hand and performing the repair. For example, emergency repairs are often needed at the most inopportune times, causing maintenance teams to scramble to get operations back online.

With the use of diagnostics, a determination can be made if a valve requires packing replacement or if there are issues with trim components. If there is a packing issue, packing can be easily replaced. If it there is a trim issue, it can be addressed by removing the existing trim and bonnet and installing a drop-in-ready trim cartridge.

Another key opportunity for utilizing trim cartridge is in shutdown and turnaround (STO) situations. Many facilities are facing declining maintenance staff and technical expertise. The time required for repairing smaller, general service control valves during STOs ties up money and expertise that otherwise could be spent on larger, more critical valves. In STOs where dozens of small globe valves need service, the time and money savings are considerable.

When valve emissions need to be reduced, the low emission packing upgrade included in a trim cartridge addresses the issue. If a plant is looking to replace their standard packing with low-emission alternatives — often required for regulatory compliance — a trim cartridge accomplishes that upgrade as part of a standard valve repair.

When a plant is faced with an overworked maintenance staff and is under pressure to make valve repairs quickly and effectively, a trim cartridge repair solution is often the best option.

Chris Roberts is the global marketing product manager for Fisher easy-e control valves at Emerson. Before joining Emerson, Chris worked for one of the company’s Impact Partners, Stover Controls, as a program manager and marketing lead. He holds a BS degree in Business Management from Iowa State University.

Emerson

Category

Tag List

Recent Posts